Correcting The Mistakes

/As with all fabrication and manufacturing, if you make a mistake cutting something it can’t usually be undone. When it comes to subtractive manufacturing, like CNC machining, then you really can replace the metal once it’s milled away.

On the eve of building some ride sections, I had the idea to modify the snazzy building tools I made last week. Since the outside post dimension is what I choose to govern the ride width, I milled out the slot a bit wider than the original 0.25 inches.

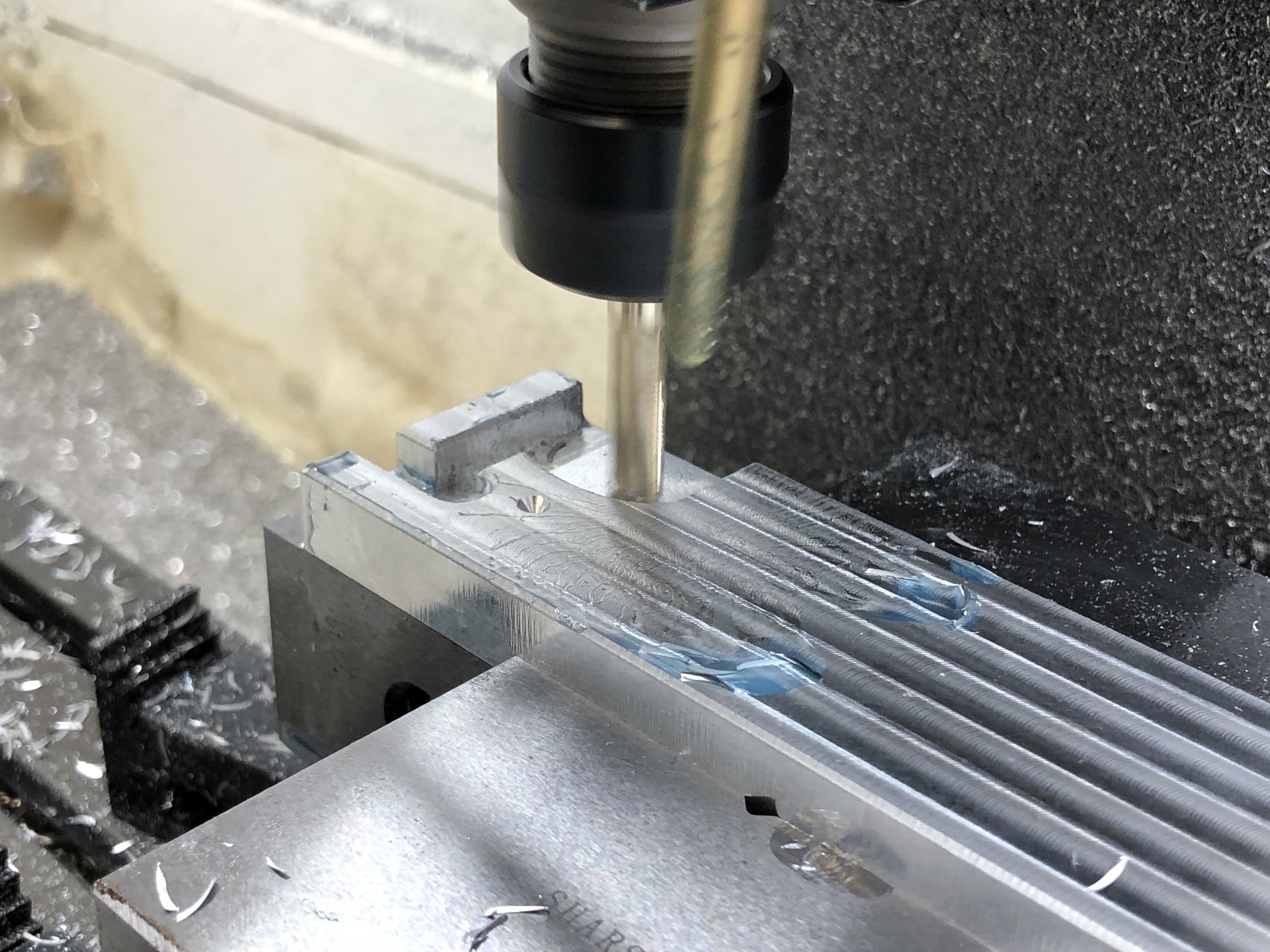

Since these parts were already milled, I had to accurately locate the part in all coordinates. This was a good time to use my z-axis touch off setter. It worked well. The only drawback is that it’s 50mm in height, and I am limited with my z-axis travel on my little mill.

Now the error on my part...

I didn’t mill deep enough when widening the pockets on the parts. So, I tried to manually control the mill. Sadly, I happened to run the end mill into the finished edge. This now makes my out-to-out distance 4.78” instead of the design 4.75”. I know, it’s only a 32nd of an inch, but the upper section is dead on at the latter of the two numbers. It should be okay for some test bent sections and a model track, but for the final rides it has to be redone.

In summary, don’t mess up. It sucks tremendous ass, and it takes more time. Focus on not rushing and always triple check measurements. Especially if they are created in a computer program to be run by another computer. Garbage in equals garbage out. However, I will have a video out soon showing some ride building. Later there will be a video of making the foundation anchors, too.

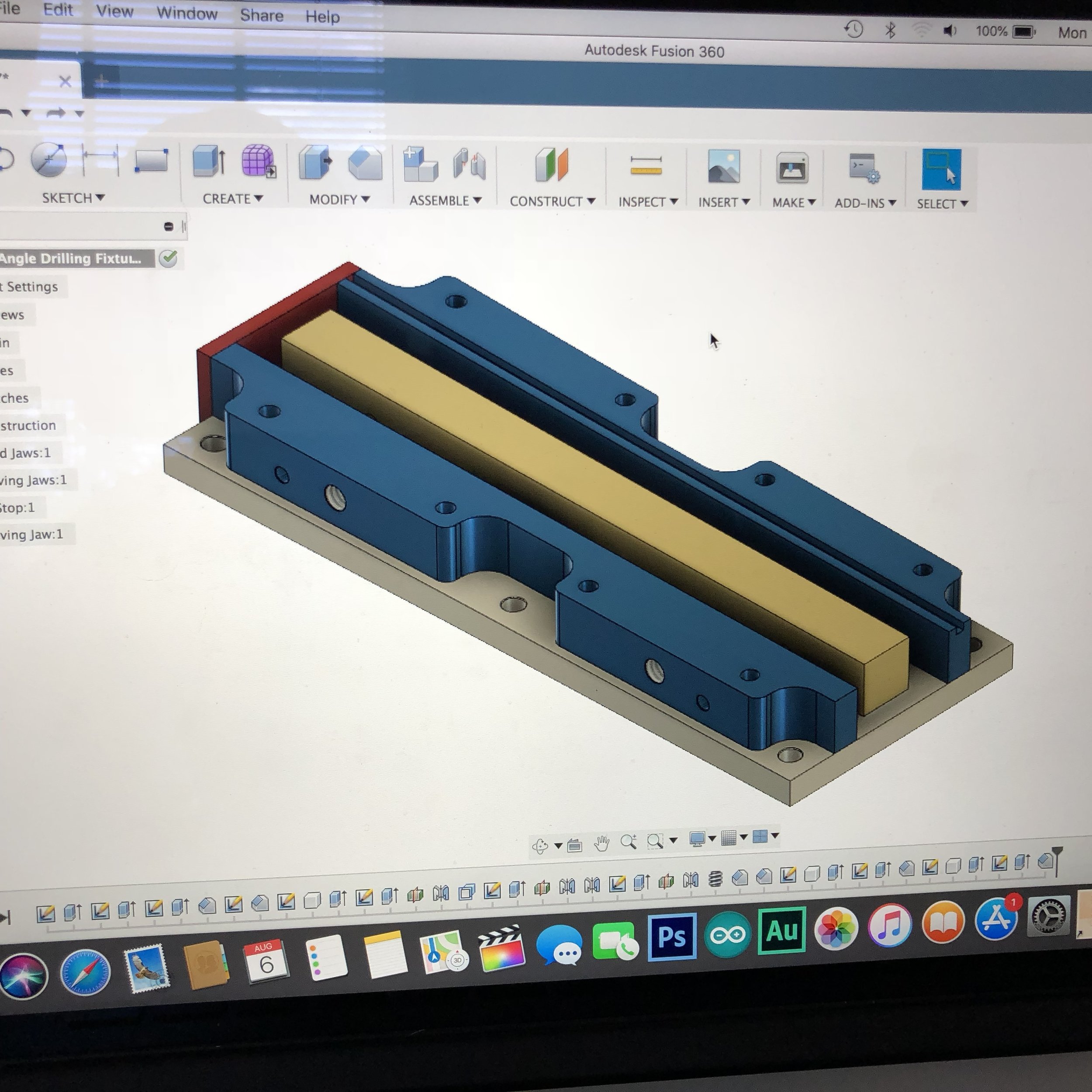

A custom work vise for my foundation anchors!