Bent Building Tools

/This week I have been focused on creating the necessary bent building tools to ensure accurate and repeatable parts. From the video last week, I machined a miniature version of the "bent builder" tool I will be using for the mini coasters. However, this week is focused on the larger scale ride which is 1/24th the size of the real thing. In other words, it's massive.

The post spacing is 4.5 inches.

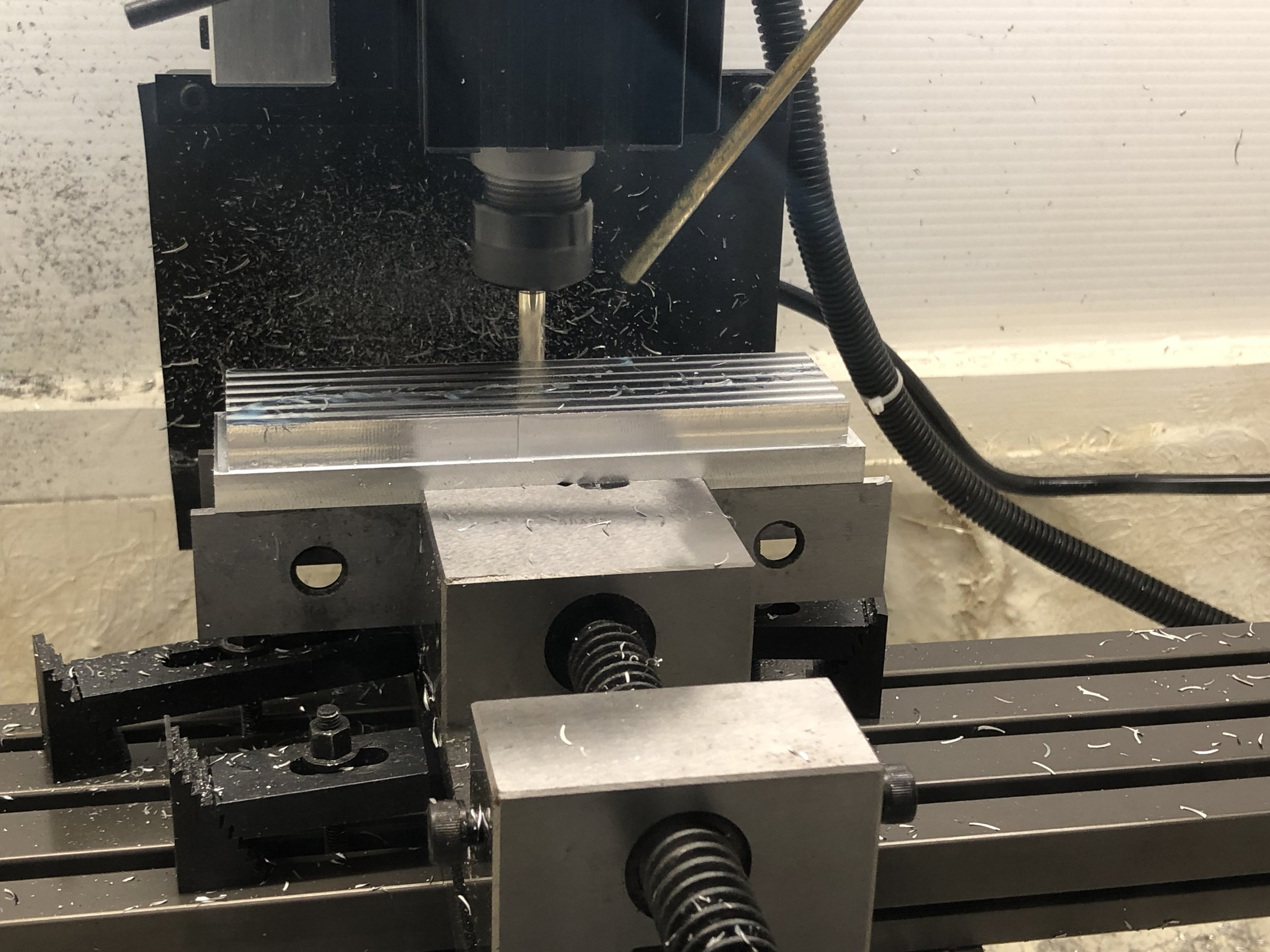

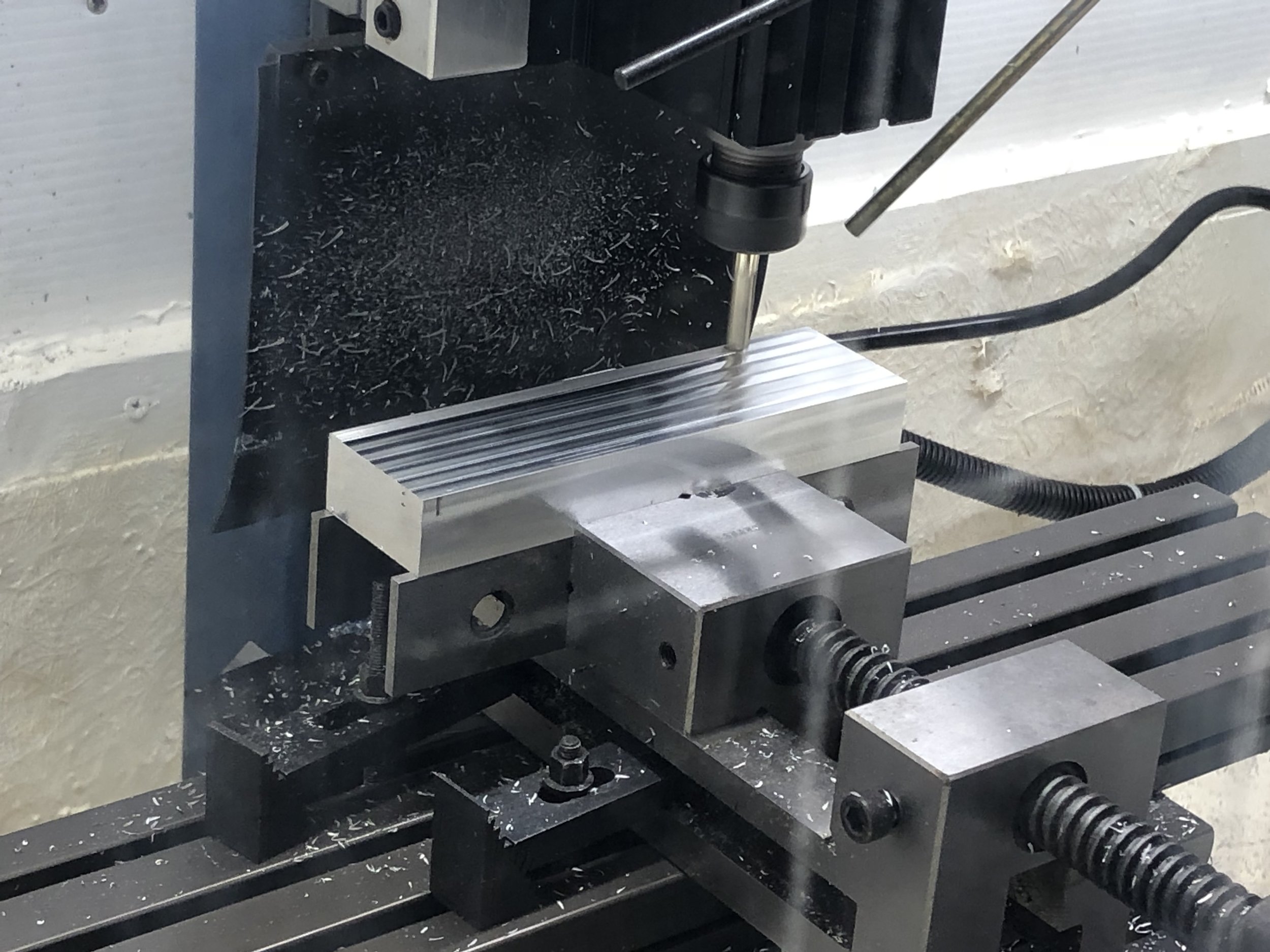

You'll notice that the size of the stock being machined in the pictures above is much larger than what was featured in last week's video. One thing to make sure of when working with large parts and a smaller vise is keeping the part against the parallels and that you have adequate clamping pressure.

The parallels are machine ground to be flat within 0.0001", at least these particular ones.

This week's video will be focused on the fully bent building tool, and there will be a threaded rod with two support rods added. Ideally, this will help create structure rapidly and accurately.

When you get tired of watching the mill doing it's thing...

You can see, somewhat, the chip pan filling up with more and more aluminum. Once there is a significant amount, I will recycle it. The key is not to cross contaminate one metal with another.

In all, the mill is running well and I have had no fails this week...but there's still time.

Another fixture to build this week, which will be in next week's video is my anchor vise. This self-made vise will allow me to make my anchor angle aluminum parts rapidly. Since there will be so many posts, I will need to make a great deal of them. I will also have to make a cutting jib to use on my band saw. But, one thing at a time.

In the picture above, you can see the difference an old (left) versus new (right) end mill produces. The larger part is, and I mean this, the best thing I've machined so far. Back in my 3D printing days, I refined my process fairly well. Now, it seems that I am finally getting the hang of machining. The one thing I didn't account for on the new end mill is that there is a slight corner radius; however, the part is smooth and shiny as can be.